|

|

Click to return to front page |

By Frank Sharman

EARLY INDUSTRIAL DEVELOPMENT

up to about 1790

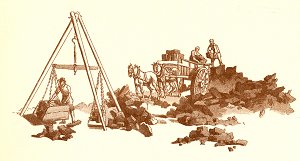

This page is decorated with

drawings from Pyne's Microcosm of 1808. They are not

specifically of Bilston but show the kind of work that would have

been going on there in the 18th century.

Agriculture was certainly,

for centuries, Bilston’s main industry. Originally it would not

have been much more than subsistence farming but, as surpluses were

produced and an expanding economy made specialisation possible,

sales and exchanges in a market would have developed. Bilston, as

we have seen, had a market from an early date and it was centred on

the market cross. The medieval market probably served only local

needs but would have gradually expanded, though probably limited, or

at least slowed down, by the proximity of the large, regional

market, at Wolverhampton. Bilston market may have had some dealings

in wool, as wool was the mainstay of the English medieval economy.

The streets and alleys called “Folds” possible reflect this industry

but it is most likely that the major trade in Bilston wool was

through the very large wool market in Wolverhampton. On the other

hand nearly all wool eventually went through London and London

merchants and, Bilston being on the main road to London and on the

London side of Wolverhampton, it is possible that Bilston people

traded directly with passing merchants. In fact, in England

generally, far more wool was sold directly to merchants than was

sold through markets and Bilston was well placed for this sort of

trading.

|

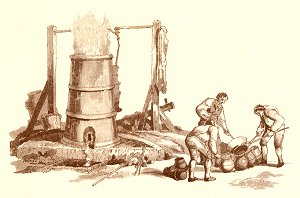

Brickmaking - and note the

women doing all the work here - was carried out as near

to the building site as possible. From time to

time kilns would have sprung up in various parts of

Bilston. |

|

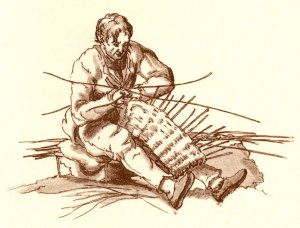

Basket making. Baskets

were used for all sort of thing and would, for instance,

have been far commoner than buckets. Bilston would

have been big enough by now to support all sorts of

craft workers. |

A more specialised

agricultural product was flax, which was not only grown in the

locality but processed too. The parish registers contain many

references to flax workers especially flax dressers. Presumably the

large amount of water needed for retting the flax came from the

brook. The market would also have

been a principal outlet for local artisans, of the sort which

existed in every place of any size – makers of footwear and

clothing, corn and seed merchants, carpenters and joiners, and the

like.

When other industries

started in Bilston is not clear but we know that by the 1700s

several industries had appeared and these are detailed below. But

before embarking on that it might be as well to observe that to say

that Bilston’s industries developed because there was coal, iron ore

and limestone underlying it, is not a sufficient explanation. (It

might also be pointed out that there was no very great water supply

in Bilston and that good means of transport to areas of consumption

were conspicuously lacking). In addition to the raw materials you

need knowledge and entrepreneurial skills and it must have been

those characteristics which enabled Bilston to develop

industrially. They would have been hampered by the lack of a river

for water and distribution, but perhaps helped by the fact that

there was no large landowner to hamper development by withholding

land and no guilds to stifle the widening of skills.

Dr. Rowlands says that by

the end of the 1600s it was the local gentry who were exploiting the

mineral wealth of the area: “Mr. Hoo of Bradley had a quarry of

building stone, and William Robbins of the Mansion house had a

coal-work at the Croft, where in 1692 he employed Benjamin Wood of

London to build him an engine to draw water there, which required

four men to keep it going. Samuel Pipe, esquire, had an agreement

with William Clarke, coalmaster, of Wednesbury to get coal and

iron”.

But things were changing:

by 1760 “the Hoo family had much increased their interests becoming

lords of the manors of Bradley, Barr and Wednesbury, but ceased to

reside in Bilston after 1720. The Perrys too, in their many

branches, scattered. The Pipe family died out. William Robbins

lived fifteen miles away and ‘only came over to collect his rents or

more often sent for them’. Later he moved to London. New men with

new fortunes made from new trades came to the fore. In the short

period between 1716 and 1730 when trades are given in the register

there are 240 references to buckle-makers, 61 to toy-makers and 44

to chape-makers. These trades readily adapted to the introduction

of japanning and enamelling about 1720”.

|

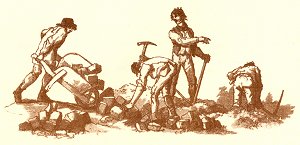

Men paving (or paying) a road.

Highways were supposed to be maintained by the parish

council and every man in the village was supposed to

contribute day labour to the work. The system

worked badly. |

It might also be noted that

all of these industries, with a few exceptions such as iron

production, can be described as cottage industries, in that they

were usually run, on a small scale, by large numbers of people

operating on their own in their own houses and backyards. They

would mostly have sold their products not directly to the consumer

but to “factors”, who bought from many makers and sold the bulk of

good thus accumulated to merchants, wholesalers and retailers. If,

for instance, we think that Bilston mass produced enamelled boxes we

have to remember that this was not mass production as we know it

today, with everything being produced by a large company in a large

factory; but it was mostly a very large number of individuals and

family, each producing small quantities. But there are indications

of bigger operations, employing people outside the family, in both

enamelling and japanning.

1. Coal mining

It is well known that coal,

of high quality and in many thick seams, underlies most of Bilston.

The earliest reference to the mining of coal which Lawley gives is

one of 1315.At that time coal was not much used

for any purpose – wood was too plentiful and the making

of charcoal was widely practised. |

|

But in time, with the near exhaustion of wood and

charcoal, coal became more and more in demand for domestic and

industrial purposes and the good people of Bilston did all they

could to meet this demand – short of working the mines efficiently.

The whole area around, and even within, the village, was covered by

small bell pits. This industry continued, to some extent at least,

until the early 20th century but most of the pits had

been worked out before then. Nearly all the mining was carried out

by one man/family operations.

2. Stone and Sand

Quarrying

|

The first material to be

quarried in Bilston was stone for grindstones, the local stone being

of a very fine grain and producing high quality grindstones. This

work continued into the 20th century. Plott says: “The

grinding stones dug at Bilston are so fine, and of so small a grit,

that they are only useful for thin edged tools, such as knives,

razors, &c. and are better than the grinding stones brought out of

Derbyshire”. |

A second material to be

quarried was casting sand. Plott’s Natural History of Staffordshire

mentions it: “I met with a sort of sand at Bilston, so very fine

that it is hardly palpable. It is of a deep orange colour and it is

sent for by artists living at a great distance and used by them to

cast metal with”.

And the third, and

commercially most important quarry activity, was for limestone,

which was used in part for agricultural purposes, though mainly, and

more and more, as a vital flux in the making of iron and steel.

3. Buckle and chape

making

Technically a buckle

consists of two parts: the “chape” is the operative part, which

acts as a bearing for the “ring” which is the decorative part; the

ring is attached to the front of the chape to make a complete

buckle. There is no date for the start of this trade in Bilston.

It may have been there from early agricultural days and was

certainly there by the middle of the 18th century.

Although buckle makers continue to appear in the records it is chape

making which predominates and in the 18th and 19th

centuries Bilston was making many, probably most, of the chapes

which were turned into buckles in the Wolverhampton buckle making

industry. Why this industry should have developed and flourished in

Bilston is not clear but it may be derived from supplying the

buckles and other metal items which were need for the harnesses of

farm draught animals.

Chapes and buckles were made

in small family concerns who would have sold complete buckles to

factors; and chapes to Wolverhampton (and probably Walsall) buckle

makers. The Rev. Ames noted, in 1729, that his two nephews, who

were buckle makers, “began to work in the shop of my house att

Priestfields”. They seem to have worked on their own account and in

a workshop attached to the house – a typical arrangement. The

registers kept by Ames include many other references to bucklemakers.

4. Lock making

It might be worth noting

here that there was some lock making in Bilston but very little of

it. (The locks in question are security locks, not canal locks).

The trade seems to have been monopolised by Wolverhampton and

Willenhall. But some locksmiths seem to have done well. When John

Hawkesford died in 1712 he was able to include in his bequests the

sum of £5 for charitable distribution to poor widows. When his wife

died about 6 months later she left £7.10s. for the same purpose.

The first burial in the new burial ground, in 1727, was of a

locksmith, John Lees and this took place “in the presence of a large

company”.

There also seems to have

been a trade in gun locks as R. R. Angerstein gives a list of

prices: “Bilston: gunlocks, common ‘Traidel’ 15d each. Lock in

‘rest’, 6 1/2d to 7d. Wages for filing of above-mentioned locks,

6d. to 7d.”.

5. Enamelling

Enamelling was, and is, one

of Bilston’s most famous industries. Lawley says that it was

present in Bilston “well before 1750” and suggests that Dovey

Hawkesford first used enamels as a way of decorating, and adding

value to, the boxes and other small items he was making. How

Hawkesford came to be making copper boxes and other items in

Bilston, Lawley does not say. The industry soon developed and seems

to have been given a boost when workers from the Battersea factory

moved to Bilston when that factory closed. It should be noted that

the Bilston industry was not established by these workers from

Battersea, nor is it true that the Battersea work was of higher

quality than that of Bilston.

Trade remained good until

fashions changed – and some have argued that Bilston was producing

so much that enamelled wares became commonplace and therefore

unfashionable. The trade seems gradually to have disappeared during

the 19th century, though perhaps not completely.

Enamelling on larger sizes of domestic wares took place on a large

scale in Bilston in the 19th and 20th

centuries, especially after T & C Clark, the local iron founders,

discovered a way of enamelling on iron and steel. But small scale

decorative enamelling may still have been around: when Susan

Benjamin revived the trade in the late 20th century she

was able to find people in Bilston who still knew how to do it. The

crafts had many local revivals in the second half of the twentieth

century.

6. Glass

There was a glass factory,

probably producing mainly cheap bottles and window glass, at Bradley

from 1674 to 1790 but it never developed into a large industry,

Stourbridge gaining a virtual monopoly. Glasshouse Bridge remembers

the site of these works.

7. Japanning

The first reference to

japanning appears in 1710. At first it may have been wooden items

that were decorated in this way but papier mache soon replaced it

and, when thin steel sheet became readily available and cheap, that

replaced papier mache in Bilston almost entirely (though it did not

in Wolverhampton). Bilston seems to have specialised in making

blank trays for supply to Wolverhampton japanners; and finished

products of a cheaper and gaudier type than Wolverhampton’s which

are said to have been exported in large quantities to South

America. Japanning and tin plate work continued well into the 20th

century.

8. Iron and Steel

|

John Wilkinson set up in Bradley

in 1767. It was an area well supplied with

ironstone, limestone and coal, if not with water.

There may well have been small

scale iron production in the area long before Wilkinson

arrived but it is from his time that we can date this

industry which was to become the chief industry of

Bilston and the pride of the town. |

|

Large steel works, supplying, it seems, the whole world,

started to spring up all over the area. As we will see these

eventually lessened in number until only Hickman’s was left; it

survived well into the 20th century.

|

|

Return to

After the Conquest |

Proceed to

18th Century Bilston |